Bigger really is better for pens

Robert Outram examines why so many salmon farmers are switching up to bigger pens.

Take a look at any recent plans for new salmon farms in Scotland, or upgrades to existing farms, and you are likely to see that 160 metre pens feature as part of the development.

These pens, or cages, are considerably larger than what counted as the norm just a few years ago. But is it just about larger pens accommodating more fish? It turns out that the reasons to upgrade in this way are actually more complicated than that.

Scottish Sea Farms recently reported that its first site to switch to 160m pens has seen record tonnage at an average harvest weight of 6.8kg, along with improved fish welfare and reduced seal predation.

Fishnish A off Mull, off Scotland’s west coast, saw ten 100m pens replaced with four 160m circumference pens.

As well as the bigger pens and heavier moorings, Fishnish also introduced Midgard HDPE knotted nets and a new winch system, and trialled a smart feeding regime, in an investment of around £3 million.

Farm Manager Alastair Fraser says: “It was night and day compared to the previous set-up: so simple, less labour intensive, with less manual handling. The new winch system is another world and once we got the hang of it, there was no going back.”

Ten winches are fitted to each walkway and operated remotely from a dedicated workboat, providing better net control and improving staff safety.

“Dealing with three instead of 10 pens (we kept one spare for handling or freshwater treating) allowed us to stay focused on the task in hand and carry out any treatments much faster.”

The combined tonnage for Fishnish A and B, where half the crop was moved after six months, was just over 4,000 tonnes, said Fraser. The company sees this as quite an achievement given challenges which included the micro jellyfish that affected most of the sector between 2022 and 2023.

Fraser attributes the results to good husbandry as well as to the bigger pens, which provide lower stocking density and better water flow and oxygen.

The new feeding system, involving motorised smart spreaders, produced “fantastic results’’, he says, ensuring the whole population was fed at the same time, with feeding finished by 9.30am so the fish could go down to the depths of the pen.

With the fish harvested over summer, the team is now preparing for the next cycle and hoping to roll out similar infrastructure at neighbouring Fishnish B.

And while they will do some things differently, such as increasing the ratio of wrasse in the pens to better handle sea lice off Mull, they are convinced the new infrastructure has paid off.

As Fraser puts it: “The team realised they’d had a hard crop but saw the benefits of this new way of farming and morale was definitely better.”

Reasons to go big

Anne Anderson, Head of Sustainability & Development, Scottish Sea Farms, says: “The move to larger pens is a deliberate strategy to support fish welfare and farm husbandry.

“The exact sizing on a farm is site-specific as there are multiple factors to take into account when assessing farm modernisation options. Importantly, maintaining our RSPCA Assured approved stocking densities means that the depth of a location is a key consideration in pen sizing.

“Other aspects that are considered are wave height, the tidal strength and current speeds at multiple depths of the pen net.”

Larger pens mean improved welfare, she argues, for both fish and for the people who tend them.

As Anderson explains: “Increasing the space between pens aids water flow within and around the farm, while in seal-prone areas a larger pen allows fish to shoal further away from a circling predator, reducing stress. Fewer larger pens also mean that we can be swifter in a full farm health treatment, if and when required.

“For our teams on-site, the larger, more robust pens allow bigger vessels to come alongside to support farmers and accommodate husbandry aids such as net winches. They are also more stable with wider walkways, meaning improved working conditions for colleagues.”

Taking pens up to this kind of size has required improved design, in terms of engineering and materials, on the part of manufacturers. It also entails investment in supporting technology such as cranes and winches to handle bigger, heavier nets.

The new standard?

The plan for Cooke Scotland’s offshore organic salmon farm at East Moclett, Orkney, which received planning permission in 2022, comprises six 160-metre pens.

Cooke Scotland says: “Larger pens can be considered for several reasons including the increased scale and advancement in technology. Generally new farms will utilise larger pens, but when redeveloping existing farms you may still see ‘smaller’ pens deployed, often due to spatial constraints.

“Fewer, larger units mean you can treat and feed a farm faster and there’s also more resilience for stock against predators compared to smaller, shallower nets, as there can be more ‘space’ in the centre of a net.

Although larger pens can come with an increase in cost for nets, equipment and also a need for bigger vessels to service a site, they can be more resilient at increasingly exposed locations in terms of more buoyancy/stability and larger walkways for staff. They can be safer in terms of mooring and working alongside larger wellboats, improving operational efficiency.”

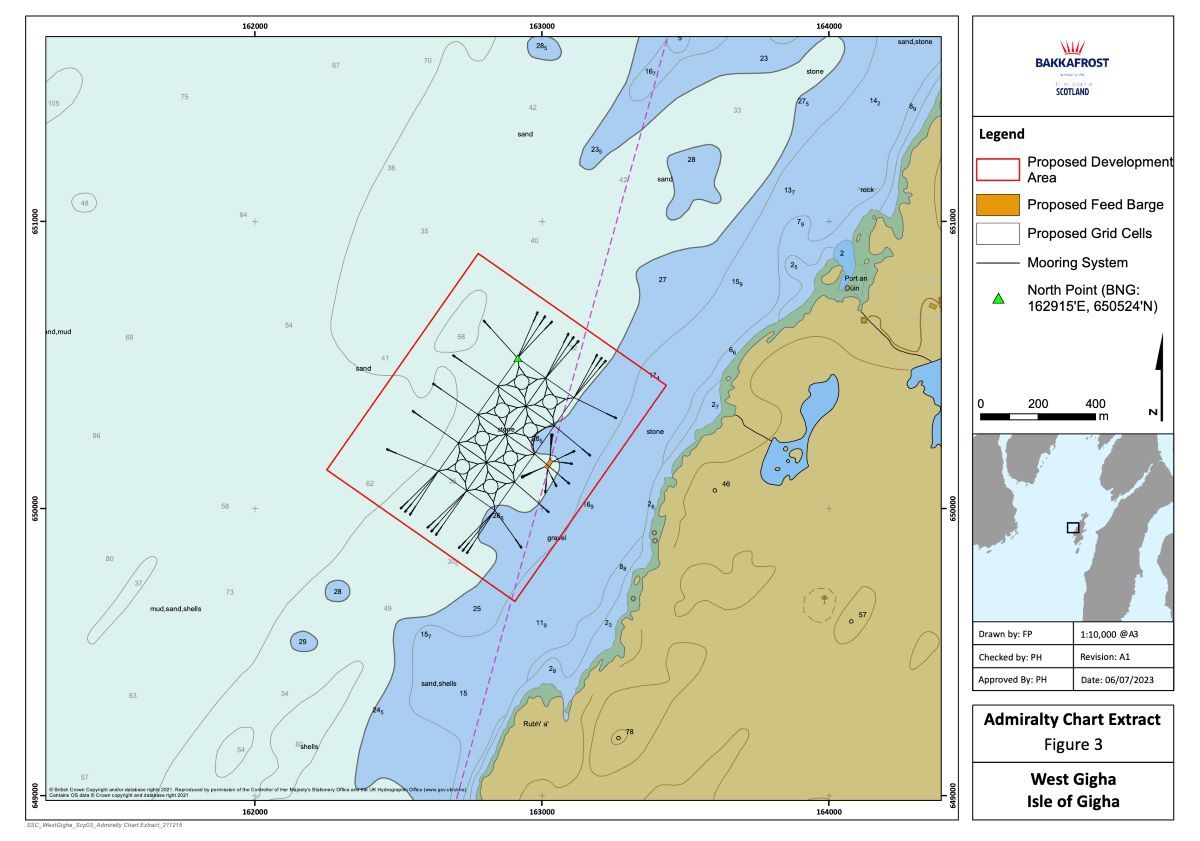

Bakkafrost’s planned new farm site off the small island of Gigha, for which planning permission was granted in November 2024, involves eight circular pens, each with a circumference of 160m, as well as a 600-tonne feed barge. The pens will be placed in a 120-metre-by-120-metre mooring grid matrix, held in two linear rows of four pens.

And at Mowi’s Loch Hourn site, on Scotland’s west coast, the company installed seven 160m pens, which have replaced 12 x 120m pens.

Speaking when the first smolts were successfully transferred to the new site in 2022, Stephen MacIntyre, Head of Environment, said: “The salmon farm at Loch Hourn has been well established for 30 years. In that time, it has been a successful operation from an economic, environmental, and social viewpoint. Mowi’s investment in this new larger pen and net technology will ensure that the farm continues to be successful in the future as fish farming in Scotland evolves.”

Larger pens have been the norm in the Norwegian industry for some time – they now appear to be the new standard for Scotland as well.

Looking to upgrade your pens? Check our online business directory for net makers, turnkey solutions, maintenance providers and sea farming equipment suppliers.