A matter of taste: a new solution for off-flavours in RAS systems

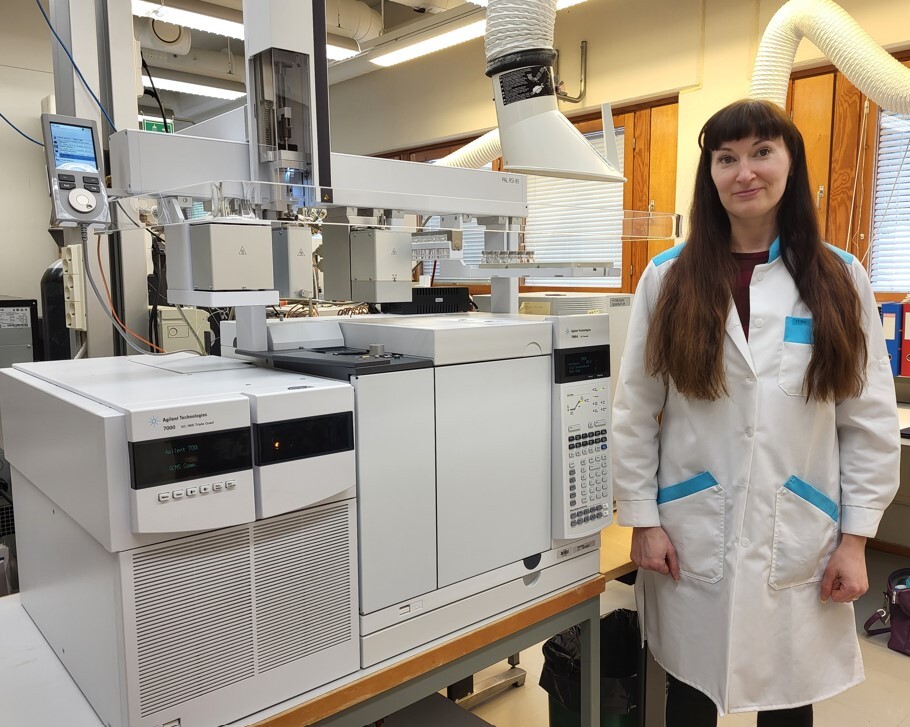

Scientists in Finland have come up with a novel solution for off-flavours in RAS systems.

So-called “off-flavours” in fish and water mould cause significant economic losses to fish farming globally. They pose a particular problem for recirculating aquaculture systems (RAS).

Typically caused by the proliferation of microbes in the system, substances such as geosmin are not normally harmful to either people or fish, but they create an unpleasant, earthy flavour to which humans are extremely sensitive.

Water mould is also a common problem in fish farms globally. In salmonid farming, this has been estimated to cause production losses of up to 10% per year through all stages of production.

Now, the Natural Resources Institute Finland (Luke) and VTT Technical Research Centre of Finland have developed capture solutions based on chemically treated cellulose fibre materials to address these challenges.

As Luke’s Research Manager and Senior Scientist, Petra Lindholm-Lehto explains, cellulose fibres were originally used by VTT for hormone capture in wastewater*. The aim was to use the wood-based cellulose fibre yarn, coated with chemicals, to capture ethinylestradiol (EE2), a hormone used in contraceptive pills, and ensure it did not get into the water supply.

Lindholm-Lehto says: “Their group is our partner here and they are experts in modifying cellulose-based material. In this case, the fibre material was chemically modified to selectively capture the off-flavour compounds.”

The capture of off-flavour compounds was studied at Luke’s experimental aquaculture facility in Laukaa. The concentrations of 14 off-flavour compounds were tested in a recirculating aquaculture (RAS) environment, where part of the water was recirculated through a fibre material. The chemically treated fibre material accumulated up to 1,000 times higher concentrations of off-flavour compounds compared to those in untreated water. After the treatment, the concentrations of off-flavours in the fish remained below the sensory thresholds.

Petra Lindholm-Lehto says: “This is a very interesting result, as no new solutions have been introduced in recent years to reduce off-flavours in recirculating aquaculture systems.”

At Luke’s Enonkoski aquaculture facility, a fibre material developed specifically for the capture of water mould spores was tested. The use of the fibre material significantly reduced the amount of mould spores in the water compared to a culture tank without the material.

“Not enough is yet known about the behaviour of the water mould and studying it in fish farming is challenging.

Previously used treatments have proven to be unsafe or ineffective. The method we have developed is based on the use of harmless capture material and therefore the results of our experiments are interesting,” says Lindholm-Lehto.

Hannes Orelma, Research Team Leader at VTT, adds: “These new cellulose-based capture materials will capture water mould spores and off-flavour compounds from the water, preventing them from accumulating in the fish.”

Patent applications have been filed for both of the innovations developed by Luke and VTT. Could the idea be fully commercialised? Petra Lindholm-Lehto says: “We are open to all good options, we haven’t excluded any yet. Now we are looking for funding for further experiments to scale up and to develop the invention into a product.”

Jani Lehto, Director of Luke’s Bioeconomy and Environment Unit, says: “Our solutions can have a significant impact on the profitability of the industry. Our results are encouraging and show that these solutions have a lot of potential.

“Our next steps are to continue development of both technical solutions in commercial-scale farms and to move forward with commercialisation. We look forward to hearing from companies and operators who would like to develop these solutions further with us!”

* “Cyclodextrin-Functionalized Fiber Yarns Spun from Deep Eutectic Cellulose Solutions for Nonspecific Hormone Capture in Aqueous Matrices” (Biomacromolecules 2018, 19, 652−661) Orelma et al.

Off-flavours: a problem for RAS

Off-flavour in fish can arise from various sources, including microbial activity, feed composition and the water quality within the RAS. The most common compounds associated with off-flavour are geosmin and 2-methylisoborneol (MIB). These compounds are produced by certain types of bacteria and algae that can proliferate in the water systems of aquaculture facilities.

Microorganisms such as actinomycetes and cyanobacteria are primary culprits in the production of geosmin and MIB. These microorganisms thrive in the nutrient-rich and warm environments typical of RAS. When they proliferate, they release these compounds into the water, which are then absorbed by the fish through their gills and skin.

The feed used in RAS can also contribute to the development of off-flavour. Certain ingredients in fish feed, particularly those derived from plant sources, may contain precursor compounds that are metabolised into off-flavour substances. Additionally, the breakdown of feed remnants in the water can promote microbial growth, exacerbating the problem.

Water quality management is crucial in RAS. Poor water circulation, insufficient filtration and inadequate oxygen levels can encourage the growth of off-flavour-producing microorganisms. Maintaining optimal water quality is therefore essential to prevent the accumulation of these unwanted compounds.

Impact on consumer acceptance

The presence of off-flavour in fish can significantly impact consumer acceptance and satisfaction. Fish that taste or smell unpleasant are likely to be rejected by consumers, leading to economic losses for aquaculture operations. Off-flavour can also undermine the reputation of fish farms and reduce the perceived quality of their products.

Off-flavour not only affects direct consumer sales but also impacts the broader marketability of farmed fish.

Retailers and wholesalers may be reluctant to purchase fish from farms known to have off-flavour issues, leading to reduced demand and potential financial instability for the producers.

Though off-flavour compounds like geosmin and MIB are not harmful to human health, they can create the perception of poor quality or contamination, deterring consumers from purchasing the affected products. This can also lead to increased scrutiny and regulatory challenges for aquaculture operations.

Mitigation strategies

Addressing the issue of off-flavour in RAS requires a multifaceted approach. Several strategies can be implemented to reduce or eliminate the presence of off-flavour compounds in farmed fish.

Advanced water treatment methods, such as activated carbon filtration and ozonation, can effectively remove geosmin and MIB from the water. These treatments can reduce the concentration of off-flavour compounds, thereby minimising their absorption by the fish.

Modifying the composition of fish feed can help prevent the formation of off-flavour compounds. Incorporating high-quality feed ingredients and reducing the use of plant-based components known to contribute to off-flavour can be beneficial. Additionally, ensuring that feed is consumed promptly and does not accumulate in the system can reduce microbial growth.

Maintaining optimal water quality through regular monitoring and management is essential. Ensuring adequate water flow, efficient filtration, and appropriate oxygen levels can help create an environment less conducive to the growth of off-flavour-producing microorganisms. Regular cleaning and maintenance of the system components can also prevent biofilm formation and microbial proliferation.

Depuration is a process where fish are transferred to clean, freshwater tanks for a period before harvest. This allows the fish to purge any absorbed off-flavour compounds, resulting in improved taste and odour. Depuration can be an effective last step to ensure the marketability of the fish.

The issue of off-flavour in recirculating aquaculture systems presents a significant challenge for fish farmers.

Understanding the sources and mechanisms of off-flavour development is crucial for implementing effective mitigation strategies. By focusing on water treatment, dietary adjustments, water quality optimisation, and depuration, aquaculture operations can produce high-quality fish that meet consumer expectations and enhance marketability.