Can your farm break through the glass ceiling?

- Catfish at the ACAC

- Feed at a farm

Changing your feed could be the key to a breakthrough in RAS efficiency

For many years, the concept of recirculating aquaculture system (RAS) farming and its customised feeds were generally assumed to have reached the limits of their efficiency. While RAS still had the upper hand on traditional farming systems, with regard to both production and sustainability potential, it was believed that there was nowhere to go when it came to further improvements.

However, research at the Alltech Coppens Aqua Centre has breathed new life into RAS farming. Backing up remarkable findings with field tests and customer experiences, Alltech Coppens has provided RAS with the momentum it needed to break through its glass ceiling.

The perceived limit

A RAS is a complex artificial reproduction of an aquatic ecosystem, allowing fish farmers to increase their scale of production drastically and in a very sustainable way. RAS, compared to other ways of fish farming, requires a high initial and operational capital investment, but this start-up investment can be easily recouped when running an optimised system. The profitability of RAS depends on the productivity (kg/m3/year) of the system and, therefore, it can make a difference with a relatively high stocking density and growth rate.

However, while the functionality of a RAS seems straightforward (water in the tank circulates through the filter system and is reused), getting the set-up just right can be complicated. For fish to reach maximised growth levels, pristine water conditions are essential. Also, every RAS system is also unique, with its own optimal way to run. Some farms can spend years trying to figure out how their system can achieve the best performance and find a balance. Even the aspects that are meant to distinguish the RAS can lead to its downfall. While the system boasts the capacity for a high stocking density, its need for constantly clean water means that excess discharging of wastewater can easily become an issue if the farm is restricted in what it can do. This means that farmers will often have to compromise on desired density in order to keep waste to a minimum.

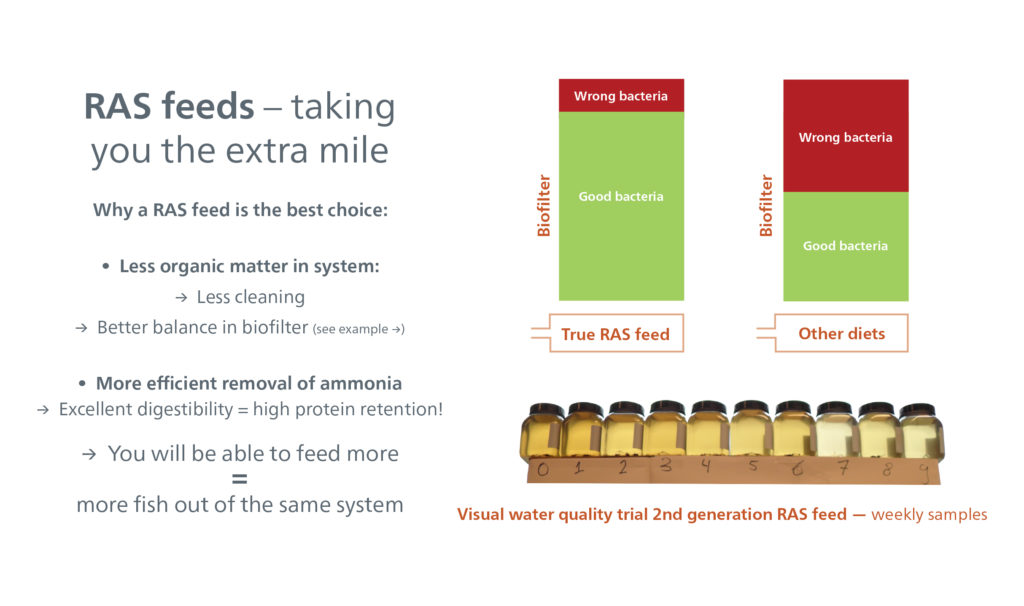

Another element that distinguishes RAS from traditional systems is the biofilter. When the water in a RAS passes through this filter, it filters out the harmful ammonia that is produced by the fish and excreted through their gills into the system. Every biofilter has a fixed surface area on which bacteria can grow and which, therefore, determines its capacity for transforming ammonia into nitrite and, eventually, the much less toxic nitrate. If the organic load is too high, the biofilter is less effective, making the overall system less efficient. It is important to bear in mind that the biofilter can only handle a certain amount of ammonia per day, which typically is related to the feed that is used.

Many of the issues farmers face can be traced back to the feed they use and how it was digested by the fish. Feed management is vital to achieving optimal performance, and pushing past previously perceived limits, in RAS. Pairing your system with a feed that complements its unique characteristics can help to optimise the water quality and, especially, oxygen levels, helping to achieve growth maximisation and providing attractive financial benefits. Using the feeds typically available on the market, however, producers could previously find no way of attempting to increase stocking density or growth rate without compromising the functionality of their system, leading many to believe that RAS could progress no further.

Exceed your maximum growth feed level

In Alltech Coppens, we have developed a line of specialised RAS feeds that significantly limit the adverse effects of feed on:

• The biofilter (and, in turn, water quality)

• total suspended solids (TSS) and

• oxygen levels.

This can lead to significantly lowered feed conversion ration (FCR) and growth exceeding the current maximum.

These RAS feeds are optimised for digestibility, resulting in better FCR because they allow high protein retention, leading to less faeces production. This saves farmers work cleaning the systems and gives a higher production potential for the same biofilter, through lower ammonia production per kilogram of feed and better-balanced biofilters.

RAS feeds – Taking you the extra mile

Customer experiences

Customer experiences in practice have shown how much of a difference this new line of RAS feeds can make. One example of this is a trial with a large trout RAS customer in Denmark, which has been ongoing for more than two years. When the farm made the switch to Alltech Coppens RAS feeds, they found that the filters could handle considerably more feed and noticed the fish were doing much better, showed lower FCR and better growth. At harvest time, they produced almost 50% more than before, in exactly the same system.

Productivity increase

Similar field observations have been seen in other species farmed in RAS, like catfish and eel. A loyal catfish producer using a competitor diet in Germany was confronted with frequent cleaning of his system due to the organic load. He then tried the Alltech Coppens dedicated RAS feed for catfish and was amazed by the outcome of the trial. Switching to this feed resulted in less time spent cleaning his system and a productivity increase of close to 50%.

Conclusion

RAS farming is nowhere near reaching its full potential. In fact, we have only begun to see how far we can push this system, and how we can change our approach to get the most out of it.

By investing in a dedicated RAS feed, you could see better growth, lower FCR and more production of fish in the same system, while maintaining a much more stable and resilient biofilter.

Your guide to optimising RAS

To learn more about RAS farming, request your copy of the Alltech Coppens RAS guide.

www.alltechcoppens.com/request-ras-guide.

![]()