Air, a natural element of defence

ODiN Titan Aeration Shields Fish Farms

CPI Equipment Inc. continues to be the leader of aeration in British Columbia, implementing its current ODiN Titan aeration system successfully in Canada and other parts of the world for many years. These aeration systems protect the farms from plankton blooms (HABs) and play a huge role in creating a healthy environment inside the pens. CPI has developed a system that works. What started out as a basic manual aeration system has now transformed into what is called ODiN Titan aeration. This system provides data tracking and is working towards AI predictive software to optimize the way it tracks HABs, maintains water quality, and facilitates the stabilisation of the in-pen environment. These systems were first developed to defend against the harsh plankton blooms on the west coast of Canada and have now expanded to help protect farms worldwide.

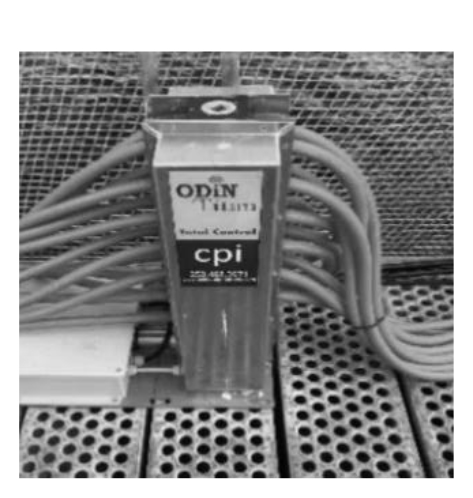

- ODiN Total Control computer system

- “You can buy a lot of things in life, but you can’t buy experience” – Kris McNichol, Founder of CPI

- Part of the ODiN Titan aeration system

CPI uses diffusers that are placed into the fish pens at various depths and each system, as a whole, is client and farm specific. The circulation of water is carefully calculated to enhance harvest, improve treatment procedures, aid in temperature control, improve water quality and protect against HABs and sea lice. The ODiN system is able to control how many CFM (cubic feet per minute) flows to each pod which reduces the amount of air required, ultimately saving money on compressor needs. Water quality is the key, and stabilising the in-pen environment is the goal. Working in partnership with the natural ocean and bringing the water up from the depths is pivotal in establishing an environment that blocks out HABs and other environmental concerns.

The latest advancement with the ODiN Titan aeration system is the introduction of this technology into the semi-closed containment pen environment. CPI recently completed a successful two year trial with Grieg Seafood in British Columbia. The trial demonstrated improved growth, better feed conversion and lower mortality. Above all, during the trial, levels of sea lice remained so low that treatments were unnecessary. CPI believes working in collaboration with industry leaders helps propel new technology so the aquaculture industry can evolve and thrive in the future.

Advancement of Air

CPI is using its ODiN Titan aeration technology in an environment where barriers are put into place to create a more controlled setting. CPIs aeration system is used in conjunction with Moleaer’s nano generators that disperse nanobubbles, producing what is being called CO2L (cool) Flow Technology, by Greig Seafoods. This technology is used to maintain barriers between farmed salmon and wild salmon and keep sea lice and HABs out of the pens. This collaboration of technology is a positive step forward for industry objectives and is paving the way for sustainable fish producers to transition to semi-closed containment.

CPI continues to work alongside their clients to design, engineer and manufacture technology that fits the needs of their farms and the evolution of the aquaculture market at large. Their commitment towards advancing technology in the aquaculture industry is unprecedented.

www.cpiequipmentinc.com

info@cpiequipmentinc.com