Increased cooling speed and shelf life with Optimice® slurry ice system

- It surrounds the fish and quickly cools it down to around -0.5°C and keeps it at this temperature during processing without freezing the fish.

- The temperature of the fish stays at around -0.5°C throughout the fishing trip, during transportation on land and on his way to the final consumer.

Great progress has been made in the handling of fish during the last few years. Research conducted by Matís, the Icelandic food and biotech research institute, the University of Akureyri (Iceland) as well as research in other countries has shown that cooling the catch immediately is a key factor in maintaining quality and prolonging shelf life.

Icelanders have developed Optimice® slurry ice as a replacement of traditional flake ice.

Optimice® is a rapid cooling system on board the ship using seawater. The liquid slurry ice surrounds the fish, quickly cooling it down below 0°C and keeping the temperature around -0.5°C. During the whole fishing trip, landing, during transport to manufacturers and at the final consumer the fish stays at the same temperature without freezing.

Therefore, the cold chain never breaks with Optimice® rapid cooling and the fish stays fresh at all times, maintaining maximum quality.

Facilitates workflow and saves time

As the Optimice® slurry ice is manufactured on board the ship, there is no need to produce flake ice on land and transport it on board.

This saves both time and money and is more convenient to work with for fishermen. The ice is simply poured in liquid form over the fish, where the liquid turns into a cold slurry ice that completely surrounds the fish and stays the whole fishing trip.

Over twenty years of worldwide experience

Optimice® has been manufactured by the company KAPP ehf since 1999. Over five hundred devices have been sold worldwide and many of the largest shipping companies in Russia, Europe, the United States, Iceland and elsewhere use the equipment successfully.

Suitable for most conditions

Great emphasis is placed on the quality, reliability and durability of Optimice® slurry ice machines, as conditions at sea can be very demanding. A reliable production and a long-lasting, low-maintenance machinery is key. Therefore, all production and inspection takes place at KAPP ehf in Iceland, following strict quality requirements and ensuring that only best quality materials are used. The liquid ice machine is available for both cold and hot climates where the sea water temperature can vary a lot. It is also suitable for both small vessels (>10m) and large trawlers and is adapted to the daily maximum catch for each vessel. The Optimice® cooling system is suitable for most fish species and has also proven successful in cooling vegetables and dough in larger bakeries, though it has been most often used for cooling demersal fish, salmon and shrimp.

Land-based fish processing

In recent years, research has shown that good results have been achieved in processing fish on land using pre-coolers from Optimice® The fish is then regularly cooled during processing so it can never heat up to the critical temperature where the growth of bacteria can occur. This increases the quality and shelf life of the fish to a large extent.

A new study from 2019 at the University of Akureyri shows that the shelf life of the fish increases by approximately one and a half days if the fish fillets are dipped in slurry ice for one minute before packing.

In the same study, the salt uptake of cod fillets with Optimice® refrigeration was investigated, showing that there is no salt uptake at all. In the study, the fish fillets were laid in a slurry ice bath from 30 seconds up to 10 minutes. The results showed that there is no significant difference in salt content depending on how long the fish was in the slurry ice bath and the salt uptake is therefore non-existent.

The cold chain may never break

A new study from 2020 at the University of Iceland examined the effect of slurry ice on the temperature in cod fillets in a fresh fish processing plant before the fish was placed into a cold storage or freezer.

The temperature of the product, refrigerant and processing rooms was monitored and the result was unambiguous. Insufficient temperature control in the fresh fish cold chain before freezing has a great impact on the quality of the final product.

It is therefore important that the cold chain is uninterrupted, from the sea to the final consumer, in order to maintain quality.

In the processing plant, the fish must therefore be cooled down quickly to storage temperature, and kept at the same temperature, to ensure maximum quality.

In another study, the temperature of the catch was studied from the sea until the catch had been processed on land.

Optimice® cooling was used on board the ship. The whole catch was cooled immediately and after seven days of fishing, the catch was landed and driven by a lorry for seven hours to the processing plant.

The temperature of the fish on arrival was -0.7°C and the ambient temperature in the processing house was +20°C. Before processing, the fish was put in a buffer tank with pre-cooled ice water.

The fish was filleted, trimmed and eventually packed, but in between it went on a conveyor belt with built-in pre-cooling.

During the whole process, the fish went from -0.7°C to +0.6°C. The increase was therefore only 0.9°C, but a lower ambient temperature would have given even better results.

The cold chain was never broken, maintaining maximum product quality from fishing and throughout the processing.

Happy customers

Customer reviews support the research results. Here are examples from people who have used the slurry ice cooling system for many years:

Ólafur Rögnvaldsson, CEO of the fish processing plant in Hellissandur. “The Optimice® equipment has proven to be excellent for our fishing vessels and our production factory on land. I recommend the equipment for everybody handling fish”.

Hinrik Kristjánsson, CEO of Kambur Seafood. “Our experience of Optimice® has been very good. The cooling stays very stable through the whole process, from catch to final customer. For us this means that we get a higher price for the fish”.

Pétur H. Pálsson, Director of Vísir fishing company. “We have used the Optimice® equipment in our fishing vessels for many years. Our experience has been outstanding. It gives us without a doubt better quality, longer shelf life, labour hours are reduced and we get a better price for our products”

Rapid cooling of the catch is key

As soon as a fish is caught, its decay begins and the sooner it gets refrigerated, the less bacteria will grow, shelf life will be prolonged and quality maintained.

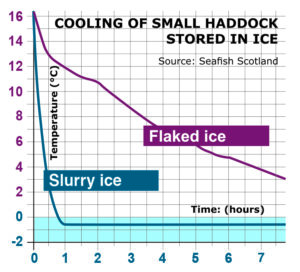

The graph above shows the difference between cooling demersal fish with Optimice® slurry ice on the one hand and traditional flaked ice on the other.

The Slurry Ice system cools the fish down to below 0°C in less than one hour. Using traditional flaked ice, it takes around fifteen hours to reach the same temperature.

The difference in quality can be seen in the photos, taken of fish after fourteen days of cooling, where the upper one is cooled with slurry ice and the lower one with flaked ice.

Numerous studies have been performed on the cooling systems and all show similar results. The graph above is from Seafish Scotland. Matís, the Icelandic Food and Biotech research institute and the University of Akureyri as well as the International Journal of Refrigeration etc. have also researched slurry ice cooling and published similar results.

Cod after 14 days of cooling.

Visual evolution during the sampling days

A study conducted at the University of Iceland clearly shows the difference in quality in fresh cod over a fourteen-day period.

The difference between these cooling systems is tremendous.

Surrounded by the slurry ice, the cod is of good quality on the fourteenth day, but in the flaked ice the quality has started to decrease a lot on the sixth day and on the fourteenth day the decay has become noticeable.

The machinery that creates Optimice® slurry ice

The pre-cooler speeds up the cooling process and is both sold separately and in conjunction with the Optimice® slurry ice machine.

The Optimice® machine creates slurry ice from seawater.

The storage tank collects slurry ice and stores it so that there is always enough ice available to cool the fish.

Rapid cooling of fish worldwide since 1999

A lot of experience has been gained in the technology as over five hundred Optimice® machines have been sold in over twenty countries around the world, both for fishing vessels and for processing on land.

Featured: The slurry ice is liquid and is poured over the freshly caught fish.