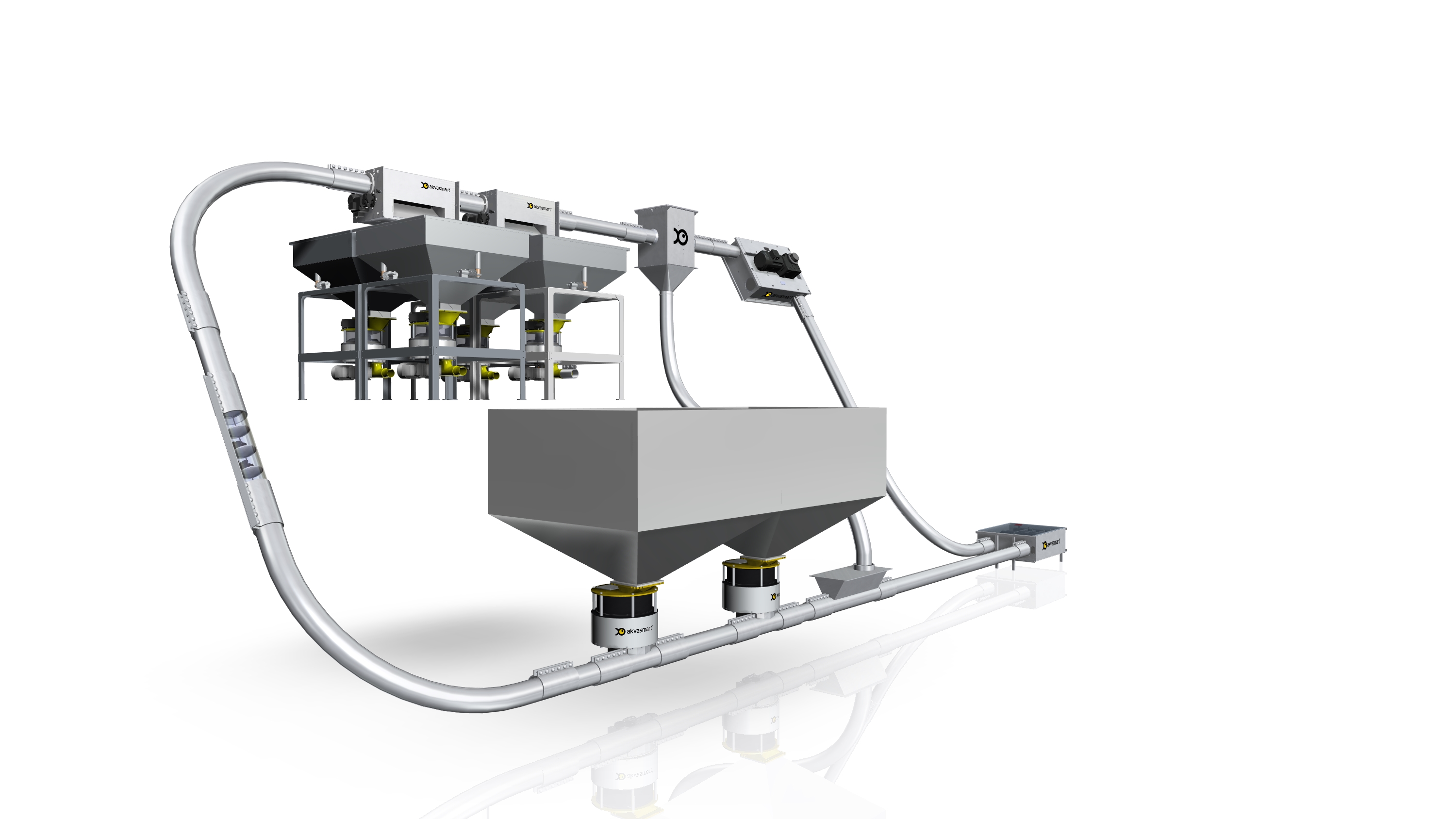

Feeding ‘revolution’ with flexible concept

A NEW feeding system that enables feed from any silo to be sent to any cage without manual handling has been launched by AKVA.

Called Flexible Feeding, the system will create higher feeding capacity as well as save time, said the company.

Flexible Feeding makes it easier to use different feed types and sizes, and allows for easy expansion of existing feed systems with more feed lines, without expensive rebuilding of main feed silos.

The system is described by AKVA as ‘a revolutionary’ new add-on concept to the well known Akvasmart CCS Feed System.

In Norwegian salmon farms, eight to 12 smaller buffer silos with weighing cells are typically installed inside the feed barge – one for each 160m circumference cage (no selector valve) – and the main feed silos are no longer connected directly to the feed lines.

A high capacity conveyor system then moves feed from the main feed silos in order to keep the buffer silos full automatically.

From there, the feed is fed through the normal central feed system to each cage. It is also possible to install selector valves after the buffer silos in case there are more cages than feed lines.

The system makes the entire feed logistics and calibration more efficient and allows easy access to different feed types and pellet sizes, said AKVA senior vice president of technology and development, Trond Severinsen.

Flexible Feeding can be adapted to both new and existing feed barges. Several rebuilds and new installations are already in operation in Norway, and two big feed barges with double conveyors are being delivered in 2018.

Today in Norway, each cage is normally connected to one specific feed silo via one single feed line. It can be time consuming switching feed pipes, calibrating and moving feed from one silo to another, said Severinsen.

The conveyor system that moves the feed from the main feed silos to the buffer silos has been developed by the American supplier Cablevey, which has supplied more than 30,000 systems over the last 40 years to major food producers worldwide.

This, however, is the first time the system has been designed and used for large scale industrial fish farming, and AKVA is the exclusive global distributor.

The entire system is controlled via AKVAconnect in the feed barge control room. It has been tested in the company’s facilities in Norway, as well as in several pilot projects with customers over the past year.

‘The results were very good and the system runs reliably,’ said AKVA. ‘The feed is gently and efficiently being transported at high speed from the main silos to the buffer silos.’

Severinsen said: ‘We are also very pleased that the system can be adapted easily to upgrade existing systems, as well as be installed in new feed barges. This means a win-win situation for both AKVA group and our customers.’

AKVA group Scotland was recognised at the Marine Aquaculture Awards, held in Aviemore on Wednesday night, winning the Business Development award. And AKVA employee Scott MacKay was joint winner of the Rising Star prize.

Picture: The new Flexible Feeding concept from AKVA